Tube Puller

In the realm of industrial machinery and engineering, the tube puller stands as a vital component, playing a crucial role in various manufacturing processes. This specialized equipment is designed to exert precise control over the extraction and positioning of tubes, ensuring accuracy and efficiency in a range of applications. From automotive engineering to medical device manufacturing, the tube puller's versatility and reliability make it an indispensable tool. In this comprehensive article, we will delve into the world of tube pullers, exploring their design, functionality, and impact on modern industries.

The Evolution of Tube Pullers: A Historical Perspective

The concept of tube pulling has evolved significantly over the years, driven by advancements in technology and the increasing demand for precision in manufacturing. Early tube pulling methods involved manual processes, often relying on skilled operators to guide and control the movement of tubes. However, these methods were labor-intensive, time-consuming, and prone to human error, leading to inconsistencies in the final products.

The development of automated tube pullers revolutionized the industry, offering a new level of precision and efficiency. The first automated tube pullers emerged in the mid-20th century, primarily designed for use in the automotive sector. These early models utilized hydraulic or pneumatic systems to control the movement of tubes, providing a more controlled and consistent pulling process. While these machines marked a significant improvement, they were often bulky, complex, and lacked the precision required for more delicate applications.

As the demand for miniaturization and precision grew across various industries, the need for more advanced tube pullers became apparent. In the 1980s and 1990s, engineers and manufacturers began to explore new designs and technologies, leading to the development of electric tube pullers. These innovative machines offered greater control and precision, allowing for finer adjustments and more intricate tube pulling operations. The introduction of electric motors and advanced control systems enabled manufacturers to achieve unprecedented levels of accuracy, making electric tube pullers the preferred choice for many industries.

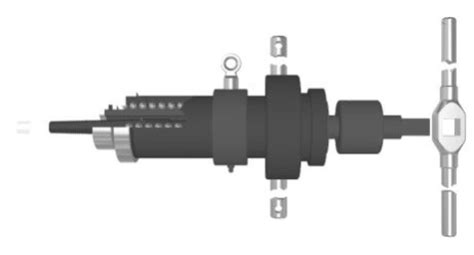

The Anatomy of a Tube Puller: Understanding the Components

A tube puller, despite its seemingly simple function, is a complex piece of machinery comprising various components, each serving a specific purpose. Understanding the anatomy of a tube puller is essential for both operators and engineers, as it provides insights into the machine’s functionality and maintenance requirements.

The Drive System

At the heart of every tube puller lies the drive system, responsible for generating the force required to pull the tube. Modern tube pullers typically utilize one of three drive systems: hydraulic, pneumatic, or electric. Each system has its advantages and is chosen based on the specific requirements of the application.

- Hydraulic Tube Pullers: These machines rely on the power of hydraulic fluid to generate force. Hydraulic tube pullers are known for their high pulling capacity and are often used in heavy-duty applications. However, they require regular maintenance and can be more complex to operate.

- Pneumatic Tube Pullers: Utilizing compressed air as the power source, pneumatic tube pullers offer a more lightweight and compact design. They are ideal for applications where precision and control are crucial, such as in the manufacturing of medical devices.

- Electric Tube Pullers: As mentioned earlier, electric tube pullers have gained popularity due to their precision and control. These machines use electric motors to generate force, allowing for fine adjustments and consistent pulling speeds. Electric tube pullers are often preferred for delicate operations and are easier to maintain compared to hydraulic or pneumatic systems.

The Clamping Mechanism

The clamping mechanism is responsible for securing the tube in place during the pulling process. It ensures that the tube remains stable and aligned, preventing any slippage or misalignment that could affect the accuracy of the operation. Various clamping designs are available, including mechanical clamps, pneumatic clamps, and even magnetic clamping systems.

Mechanical clamps, often found in older tube puller models, provide a secure grip but may require manual adjustment. Pneumatic clamps, on the other hand, offer a more automated solution, allowing for quick and precise clamping operations. Magnetic clamping systems are relatively newer and are particularly useful for non-ferrous materials, providing a strong and secure hold without the need for physical contact.

The Pulling Mechanism

The pulling mechanism is the core component of a tube puller, responsible for exerting the force required to extract the tube. Depending on the drive system, the pulling mechanism can vary in design. In hydraulic and pneumatic tube pullers, the pulling mechanism often consists of a piston or cylinder, while electric tube pullers utilize a motor and gear system to generate the pulling force.

The pulling mechanism must be capable of delivering consistent force throughout the pulling process. It should also be designed to accommodate a range of tube diameters and lengths, ensuring versatility and adaptability for different applications.

Applications and Industries: Where Tube Pullers Excel

Tube pullers find their place in a diverse range of industries, each with unique requirements and challenges. The versatility of tube pullers allows them to excel in various applications, contributing to the efficiency and precision of manufacturing processes.

Automotive Industry

The automotive industry is one of the primary sectors where tube pullers are extensively used. From exhaust systems to fuel lines and hydraulic tubes, tube pullers play a critical role in the assembly of vehicles. The precision and control offered by tube pullers ensure that tubes are positioned accurately, contributing to the overall reliability and performance of automotive components.

In automotive manufacturing, tube pullers are often used in conjunction with other automated machinery, such as robotic arms and welding systems. This integration allows for a seamless and efficient production process, where tubes are pulled, positioned, and welded with precision, resulting in high-quality automotive components.

Medical Device Manufacturing

In the realm of medical device manufacturing, precision and cleanliness are of utmost importance. Tube pullers play a vital role in the production of medical devices, such as catheters, endoscopes, and surgical instruments. These delicate and intricate devices require precise tube pulling operations to ensure their functionality and safety.

Pneumatic tube pullers are commonly used in medical device manufacturing due to their precision and clean operation. The use of compressed air eliminates the risk of contamination, making these machines ideal for producing sterile medical devices. Additionally, the fine control offered by pneumatic tube pullers allows for the precise positioning of tubes, ensuring the accuracy of the final product.

Aerospace and Defense

The aerospace and defense industries demand the highest levels of precision and reliability. Tube pullers are integral to the manufacturing of aircraft components, such as fuel lines, hydraulic systems, and cooling tubes. The precise control offered by tube pullers ensures that these critical components meet the stringent requirements of the aerospace industry.

Electric tube pullers are often preferred in aerospace applications due to their precision and ease of control. The ability to make fine adjustments and maintain consistent pulling speeds is crucial for ensuring the integrity of aircraft systems. Additionally, the compact and lightweight design of electric tube pullers makes them well-suited for use in tight spaces, a common challenge in aircraft manufacturing.

Performance Analysis: Factors Affecting Tube Puller Efficiency

The performance of a tube puller is influenced by various factors, each playing a critical role in the machine’s efficiency and accuracy. Understanding these factors is essential for operators and engineers to optimize the tube pulling process and ensure consistent results.

Tube Material and Diameter

The material and diameter of the tube being pulled are key factors affecting the performance of a tube puller. Different materials, such as stainless steel, aluminum, or copper, have varying levels of hardness and ductility, which can impact the pulling force required. Additionally, the diameter of the tube influences the clamping mechanism and the overall pulling process.

For example, pulling a thin-walled tube requires a different approach compared to a thick-walled tube. The clamping mechanism must be capable of securely holding the tube without causing any deformation or damage. Similarly, the pulling mechanism must be designed to accommodate a range of tube diameters, ensuring consistent performance regardless of the tube's size.

Tube Length and Configuration

The length and configuration of the tube also play a significant role in the tube pulling process. Longer tubes may require additional support or guidance to prevent buckling or kinking during the pulling operation. The configuration of the tube, such as whether it has bends or curves, can also impact the pulling process, as these features can introduce additional friction or resistance.

Tube pullers are often equipped with guide mechanisms or support systems to ensure the tube remains aligned and stable throughout the pulling process. These features become crucial when dealing with longer or more complex tube configurations, as they help maintain the tube's integrity and prevent any potential damage.

Environmental Factors

Environmental factors, such as temperature and humidity, can also influence the performance of a tube puller. Extreme temperatures can affect the viscosity of lubricants used in the machine, potentially impacting its performance and longevity. High humidity levels can lead to corrosion or rusting of certain components, especially in hydraulic or pneumatic systems.

To mitigate the impact of environmental factors, tube pullers are often designed with robust materials and coatings to withstand various conditions. Regular maintenance and the use of appropriate lubricants and seals can also help ensure the machine's performance and longevity, regardless of the operating environment.

Future Innovations: Enhancing Tube Puller Technology

As industries continue to evolve and demand higher levels of precision and efficiency, the development of tube puller technology is also advancing. Manufacturers and engineers are exploring new designs and features to enhance the performance and capabilities of tube pullers, pushing the boundaries of what these machines can achieve.

Smart Tube Pullers: Integration of IoT and AI

The integration of Internet of Things (IoT) and Artificial Intelligence (AI) technologies is revolutionizing the field of tube pulling. Smart tube pullers are equipped with sensors and advanced control systems, allowing for real-time monitoring and adjustment of the pulling process.

These smart tube pullers can collect data on various parameters, such as pulling force, tube position, and machine temperature. The data is then analyzed using AI algorithms to optimize the pulling process, ensuring consistent and precise results. Additionally, smart tube pullers can provide real-time alerts and diagnostics, enabling operators to address any issues promptly and prevent potential downtime.

Miniaturization and Portability

The trend towards miniaturization and portability is also influencing the design of tube pullers. Manufacturers are developing compact and lightweight tube pullers that can be easily transported and used in various locations. These portable tube pullers are particularly useful for on-site maintenance or repair work, where traditional tube pulling machinery may not be feasible.

Miniaturized tube pullers often utilize advanced materials and innovative designs to achieve a compact footprint without compromising performance. These machines are designed to be user-friendly, with intuitive controls and easy setup, making them accessible to a wider range of operators.

Sustainability and Eco-Friendly Designs

With growing environmental concerns, the development of sustainable and eco-friendly tube pullers is gaining traction. Manufacturers are exploring ways to reduce the environmental impact of tube pulling machinery, both in terms of energy consumption and waste generation.

Energy-efficient designs, such as the use of regenerative braking systems or solar-powered components, are being incorporated into tube pullers to reduce their carbon footprint. Additionally, manufacturers are focusing on developing tube pullers with recyclable materials and minimizing the use of harmful substances, contributing to a greener and more sustainable manufacturing process.

| Tube Puller Type | Advantages | Applications |

|---|---|---|

| Hydraulic Tube Pullers | High pulling capacity, suitable for heavy-duty applications | Automotive industry, construction |

| Pneumatic Tube Pullers | Precision and clean operation, ideal for medical devices | Medical device manufacturing, laboratory equipment |

| Electric Tube Pullers | Precision and control, ease of maintenance | Aerospace, electronics, precision engineering |

What are the key considerations when selecting a tube puller for a specific application?

+When choosing a tube puller, factors such as tube material, diameter, length, and the required pulling force should be considered. Additionally, the level of precision and control needed for the application, as well as the operating environment, play crucial roles in selecting the right tube puller.

How does the clamping mechanism affect the tube pulling process?

+The clamping mechanism ensures the tube is securely held during the pulling process. It prevents slippage and maintains tube alignment, contributing to the accuracy and consistency of the tube pulling operation.

What are the advantages of smart tube pullers with IoT and AI integration?

+Smart tube pullers offer real-time monitoring and optimization of the pulling process. They provide data-driven insights, ensuring consistent and precise results, while also enabling proactive maintenance and reducing downtime.